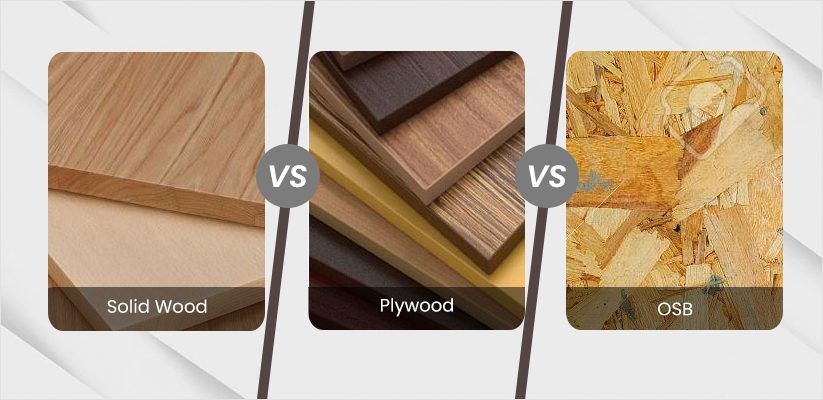

We often come across many wooden products such as cabinets, chairs, vanities, tables, etc. which are either made of solid wood or engineered wood. The question that comes to mind is What is solid wood and what is engineered wood. Solid wood is a purely natural wood obtained from any tree such as cedar, oak, maple, etc. In other words, solid wood is a lumber wood milled directly from the tree. It does not have any extra man-made ingredient. Engineered wood, on the other hand, is made of many types of materials such as wood fibers, chemicals, resins, etc. by a man-made process. The outward appearance of an engineered wood can resemble a natural wood but it is not natural.

Post your Requirement

Related Post: What are Commercial Plywood – It’s Types and Sizes

Plywood vs Solid Wood

- Solid wood refers to blocks of wood obtained from trees which are directly used for making furniture and other wooden items. Plywood, on the other hand, is made by gluing many layers of veneer with grains of each layer rotated at 90° to adjacent layer. The veneers are thin sheets obtained by peeling logs of wood.

- Solid wood is stronger than plywood since it is a single homogeneous entity. The strength of plywood depends upon the strength of the glue since it bonds multiple layers together.

- Solid wood tends to expand and contract significantly. Plywood, on the other hand, is more dimensionally stable and does not expand or contract like solid wood.

- Solid wood is suitable for applications requiring strength and stiffness such as structural supports, shelves, decking, roof rafters, decking, etc. Plywood, on the other hand, is suitable for making wooden products which should not warp, shrink or crack. Some examples include desktops, storage containers, cabinets, etc.

- Soild wood has superior aesthetics as compared to plywood. The natural wooden appearance and feel of a solid wood makes it score high in terms of aesthetics. Plywood, on the other hand, needs to be covered by a decorative material such as veneer in order to appear pleasing to the eye.

Suggested Post: MDF vs. Plywood vs. Particle Board

OSB Vs Plywood

The question is what is osb? OSB stands for Oriented Strand Board. It is also an engineered wood. OSB is a structural panel product which is manufactured by bonding thin wooden strands using adhesive. The adhesive used is waterproof and heat cured. Wax may also be added to the adhesive to enhance moisture resistance. The wooden strands are rectangular in shape and arranged in cross-oriented layers. This means that the grain direction of the outer layers is in the major longitudinal direction while that of the inner layers is in the cross direction. Such an arrangement imparts dimensional stability to the OSB panel. The layers of strands are bonded using heat and pressure. Main features of OSB are as follows.

- OSB panel is resistant against warping, deflection, cracking and delamination by virtue of the wooden strands and the adhesive used in it.

- OSB panels come in large sizes which form a solid panel devoid of gaps and voids. This reduces the number of joints and provides more thermal and sound insulation.

- OSB has a 66% share of the structural panel market which is more than plywood.

- OSB is suitable for external and internal use.

Related Post: What is MDF (Board/Wood) – Its Uses & What it is Made of

Plywood and its Types

Plywood is a type of engineered wood which is made by gluing sheets of wood veneers in such as manner that the grains of adjacent layers are at right angles to each other. The various types of plywoods are as follows.

Hardwood plywoods

Hardwood plywoods are manufactured using various species of hardwood such as red oak, birch, ash, maple, mahogany, etc. They are commonly used for making cabinets and furniture.

Suggested Post: What is Laminated Plywood- Its types and design

Softwood plywoods

Softwood plywoods are made using fir, cedar or mango wood veneers. They are used as structural building materials and make sub-floors of residential properties. Softwood plywood comes usually come in 4’X8’ sheets.

Exterior grade plywoods

Exterior grade plywood is also called Boiling Water Resistant or Boiling Water Proof grade plywood. In this type of plywood, the veneers are bonded using waterproof resins such as phenolic resins. Exterior grade plywood is used for external sheathing of buildings, as a roofing material, and as a flooring material in bathrooms and kitchens.

Related Post: What is Plywood? – Plywood Types and Its Uses

Interior grade plywoods

Interior grade plywood is also called Moisture Resistant grade plywood. They are used to make internal furniture items. Such plywood can resist humidity and moisture up to a fixed level.

Marine grade plywoods

Marine-grade plywood is used to construct boats. Such plywood is treated to withstand rotting due to prolonged exposure to moisture. Waterproof glue is used to bond the layers in marine-grade plywood.

Composite plywoods

Composite plywoods have conventional wood veneers like other plywood but the only difference is that such plywoods have two outside layers of high-density fiberboards covered by a thin veneer of hardwood. Such plywoods have the same finishing as hardwood plywood.

Post A Comment